31CrMoV9 | DIN 1.8519 Nitriding Steel in Stock

31CrMoV9 is a high-hardenability alloy nitriding structural steel according to the European standard EN10085. The numbers and element symbols in its name indicate its main components: approximately 0.31% carbon, approximately 2.25% chromium, and it also contains molybdenum and vanadium.

31CrMoV9 steel, with its high strength, high toughness, excellent high-temperature stability, and outstanding nitriding performance, occupies an important position in the high-end equipment manufacturing industry. Its unique alloy element ratio (Cr-Mo-V) makes it perform exceptionally well in high-temperature, high-fatigue, and high-wear environments, making it particularly suitable for precision parts requiring surface nitriding treatment.

31CrMoV9 Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Mo | V |

| 31CrMoV9/1.8519 | 0.27-0.34 | ≤0.4 | 0.40-0.70 | ≤0.025 | ≤0.035 | 2.3-2.7 | 0.15-0.25 | 0.1-0.2 |

31CrMoV9 Physical Properties (20℃)

- Density: 7.73 kg/dm³

- Elastic Modulus: 210 GPa

- Thermal Conductivity: 43.0 W/m·K

- Resistivity: 0.19 Ω·mm²/m

- Specific Heat Capacity: 441 J/kg·K

- Critical Point: AC₁=775℃

31CrMoV9 Forging

- Initial forging temperature: 1050-1150℃ (not exceeding 1180℃ to prevent coarse grains)

- Final forging temperature: ≥850℃ (forging below 850℃ is strictly prohibited)

- Forging ratio: ≥4:1 (to improve microstructure and enhance mechanical properties)

- Post-Forging Treatment:For 31CrMoV9 steel, the recommended practice is to perform annealing heat treatment immediately after forging.

31CrMoV9 Steel Heat Treatment

31CrMoV9 Softening Annealing (Pretreatment)

- Temperature: 680-720℃, hold for 2-4 hours

- Cooling: Slow furnace cooling (≤50℃/h)

- Purpose: To relieve internal stress, improve machinability, and reduce hardness to ≤248 HB

31CrMoV9 Quenching

- Water Quenching: 840-870℃, suitable for small cross-section parts, deeper hardened layer, but higher risk of deformation and stress concentration.

- Oil Quenching: 850-880℃, suitable for large cross-section parts (>100mm), lower quenching stress and more stable core properties, but slightly shallower hardened depth.

31CrMoV9 Tempering

Single-stage tempering: 540-680℃, hold for 2 hours, air cool.

Hardness vs. temperature:

- 680℃ tempering: approx. 24 HRC, tensile strength approx. 1000 MPa

- 620℃ tempering: approx. 28 HRC, tensile strength approx. 1050 MPa

- 560℃ tempering: approx. 32 HRC, tensile strength approx. 1150 MPa

Multi-stage tempering: First, high temperature (650℃) to relieve stress, then low temperature (200℃) to increase surface hardness, suitable for precision molds.

31CrMoV9 Mechanical properties (quenched and tempered state)

| Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction,% | Charpy Impact,J | Hardness,HB |

| 1080-1275 MPa | ≥930 MPa | ≥10% | ≥45% | ≥25 | 270-310 |

31CrMoV9 Nitriding Treatment (Surface Strengthening)

- Gas Nitriding: 480-570℃, holding time 16-100 hours

- Surface Hardness: 750-1000 HV, wear resistance improved by 3-5 times

- Deformation: Tooth profile deformation after vacuum nitriding is only 0.01-0.03mm, eliminating the need for gear grinding.

31CrMoV9 Application

| Industry | Typical applications |

| Energy and Power | Steam turbine blades, generator shafts, high-temperature and high-pressure pipelines |

| Petrochemicals | Reactors, pressure vessels, drill pipe joints |

| Automotive Manufacturing | Engine crankshafts, connecting rods, gearbox gears |

| Aerospace | Engine components, high-strength fasteners |

| Machinery Manufacturing | High-precision gears, hydraulic piston rods, precision molds |

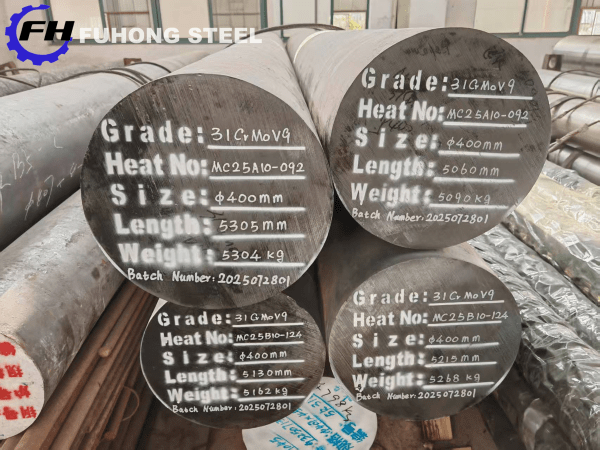

31CrMoV9 Supply Form & Size

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.20 – 90mm with UT Assurance in stock

Heat treatment: Normalizing (+N), Annealing (+A),Quenched & Tempered(QT)

Surface finish:Black / Rough turned / Peeled