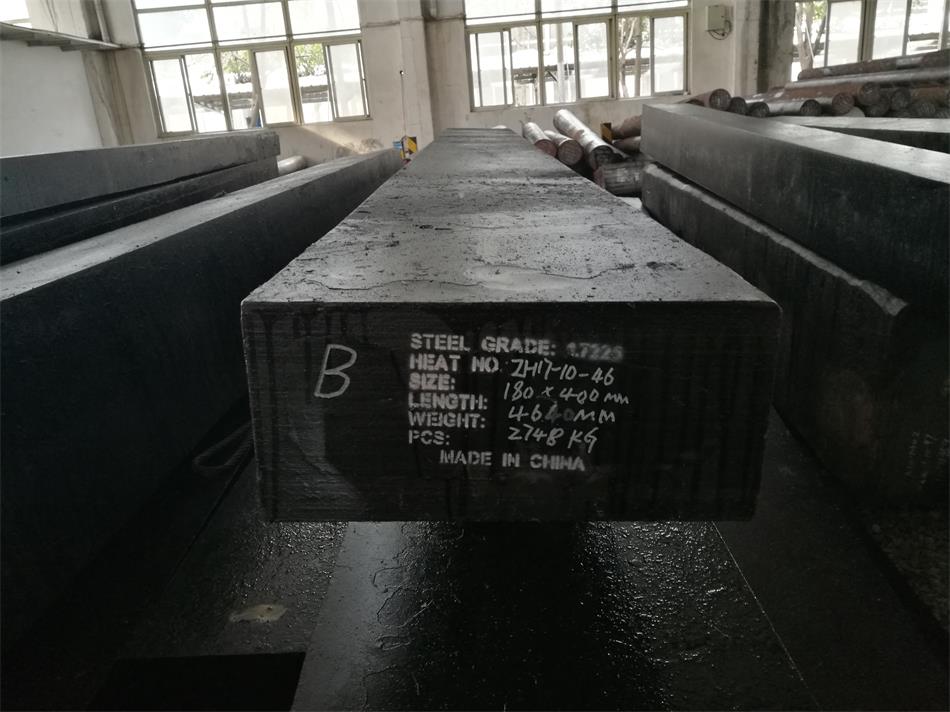

42CrMo4 Alloy Steel | DIN 1.7225

42CrMo4 is alloyed heat treatable steel which is used in quenched and tempered condition with a typical tensile strength of 900 -1200 N/mm².It has high strength,good wear-resistance,high fatigue strength and good low-temperature impact toughness.Similar to AISI 4140,SCM440,only a little different in Mn,Cr,this material also has good machinability,but poor in weldability.

1.42CrMo4 steel Supply Form & Size

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1,000 | 3,000-10,000 |

| Square bar | 100x100-600x600 | 3,000-6,000 |

| Plate/Sheet | Thickness :20-400 Width:80-1,000 | 2,000-6,000 |

| Flat bar/Blcoks | Thickness :120-800 Width:120-1,500 | 2,000-6,000 |

2.Surface Finish&Tolerance

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

3.Chemical Composition&Related Specifications

| Grade | C | Si | Mn | Cr | Mo | P | S |

| 42CrMo4/1.7225 | 0.38-0.45 | ≤ 0.4 | 0.6-0.9 | 0.9-1.2 | 0.15-0.3 | ≤ 0.025 | ≤ 0.035 |

| USA | UK | China | Japan |

| 4140 | EN19/709M40 | 42CrMo | SCM440 |

4.Mechanical Property

| Diameter d mm | ≤ 16 | 16-40 | 40-100 | 100-160 | 160-250 |

| Thickness t mm | < 8 | 8-20 | 20-60 | 60-100 | 100-160 |

| Yield Strength Mpa | ≥900 | ≥750 | ≥650 | ≥550 | ≥500 |

| Tensile Strength Mpa | 1100-1300 | 1000-1200 | 900-1100 | 800-950 | 750-900 |

| Elongation, % | ≥10 | ≥11 | ≥12 | ≥13 | ≥14 |

| Reduction of area ,% | ≥40 | ≥45 | ≥50 | ≥50 | ≥55 |

| impact,J | ≥30 | ≥35 | ≥35 | ≥35 | ≥35 |

5.Forging

1.Preheat 42CrMo4 engineering steel uniformly and slowly;

2.Increase the forging temperature up to 1150-1200°C;

3.Hold suitable time for the steel to be thoroughly heated before forge;

4.Reheat steel when temperature below 850°C;

5.Cooling as slowly as possible in still air or in sand after forged.

6.Heat Treatment

Normalizing:850℃-880℃,cool in air

Annealing:800℃-850℃,Cool in furnace,241HB Max.

Hardening:820℃-860℃,oil quench

Tempering:550°C – 650°C, cool in still air

7.Application

42CrMo4 has high strength and wear-resistance,widely used in the automotive and aircraft industry, such as axle legs, axles, drive rods, crankshafts,pinions, gearwheels, linings, link plates,belt buckles, springs, saw blades, knifes and scissors.