Christmas Tree Equipment: Why Choose 4140 Steel?

Overview: Why Choose 4140 Steel?

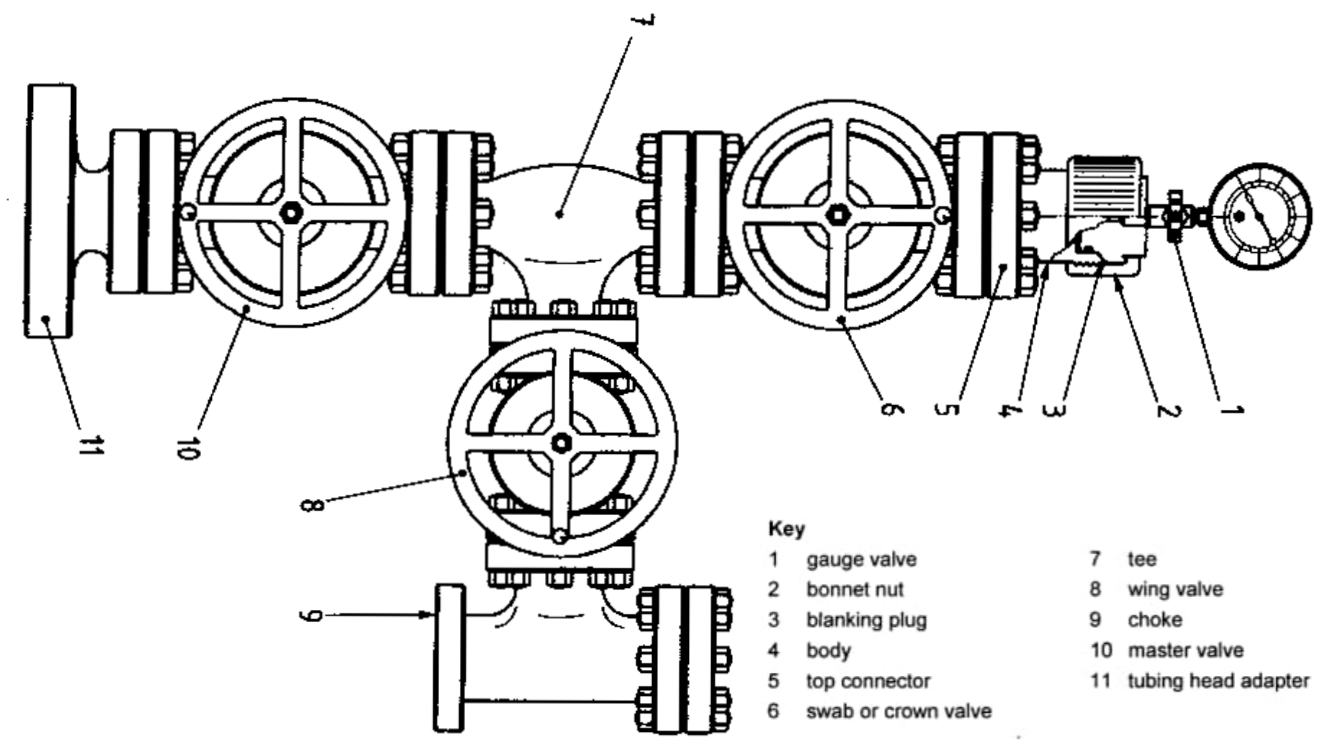

Christmas trees are core equipment crucial to oil well production and safety. They operate in extremely harsh environments, characterized by high pressure, cyclical loads, and potentially corrosive media (salt water, CO₂, and H₂S).

4140 steel, through quenching and tempering heat treatment (quenching followed by high-temperature tempering), achieves an optimal combination of high strength, high toughness, and good fatigue strength, making it an ideal choice for manufacturing critical pressure-bearing components of Christmas trees, achieving a balance between safety and cost-effectiveness.

1.High Strength and Toughness

- Reason: Wellhead pressures in oil and gas wells can reach 10,000 psi (approximately 69 MPa) or higher, with pressures even higher in deep and ultra-deep wells. Materials must possess extremely high yield strength and tensile strength to withstand this static pressure, while also possessing good toughness to prevent brittle fracture under pressure fluctuations or shock loads.

- Advantages of 4140: Through quenching and tempering heat treatment (quenching followed by high-temperature tempering), 4140 steel achieves an excellent combination of strength (up to approximately 1500 MPa tensile strength) and toughness. This allows components to withstand higher pressures with reduced wall thickness, resulting in lighter and safer equipment.

2.Good Fatigue Resistance

- Reason: During oil well production, pressure is not constant. Frequent valve opening and closing, throttle vibration, and water hammer all generate alternating stresses that can lead to metal fatigue.

- Advantages of 4140: Properly heat-treated 4140 steel has a high fatigue limit, better able to withstand cyclic loads and extend equipment life.

3.Moderate Corrosion Resistance

- Reason: Oil and gas fluids often contain corrosive media such as brine, CO₂ (carbon dioxide), and H₂S (hydrogen sulfide, a sour gas).

- Advantages of 4140: 4140 steel is a low-alloy steel, and its corrosion resistance is inferior to that of stainless steel. Therefore, in corrosive environments, all Christmas tree components made of 4140 steel must undergo rigorous surface anti-corrosion treatments (such as electroless nickel plating and epoxy coating). For extremely harsh sulfur-containing environments (sour environments), corrosion-resistant alloys (CRAs) such as 825 and 718 are often used directly. However, 4140 with nickel-phosphorus plating can be used in moderately corrosive environments.

4.Excellent Machinability

- Reason: Christmas tree components have complex structures and require high precision.

- Advantages of 4140: In the annealed state, 4140 steel has a relatively low hardness, making it easy to machine using processes such as turning, milling, drilling, and planing, enabling the production of complex, dimensionally precise parts. After machining, it undergoes a final heat treatment to achieve the desired mechanical properties.

5.Cost-Effectiveness

Compared to higher-end materials such as duplex stainless steel and nickel-based alloys, 4140 steel is significantly less expensive. The “carbon steel/low-alloy steel base + high-performance anti-corrosion coating” approach effectively controls manufacturing costs while meeting most operating requirements.

Application and Performance Requirements

Christmas tree components can be divided into three categories, each with specific performance requirements for 4140 steel.

1. High-Pressure Valve Body (Core Application)

Application Components: Main valve bodies and flow paths in main valves, production wing valves, casing valves, switching valves, and Christmas tree bodies.

Operating Characteristics: Withstands the highest static pressures and the greatest pressure fluctuations (water hammer, valve opening and closing), representing the primary pressure boundary.

Core Performance Requirements:

- Ultra-High Strength: Must possess extremely high yield strength and tensile strength to withstand wellhead pressures and prevent plastic deformation and bursting.

–Required Specifications: Yield Strength (YS) ≥ 758 MPa (110 ksi), Untensive Tensile Strength (UTS) ≥ 931 MPa (135 ksi).

- High Toughness: Prevents catastrophic brittle fracture under pressure shock or low-temperature conditions.

-Required Performance: Charpy V-notch impact energy (at -18°C / 0°F) average ≥ 54 J (40 ft-lbf), with a minimum individual value ≥ 47 J (35 ft-lbf).

- Excellent fatigue resistance: Capable of withstanding tens of thousands or even millions of pressure cycles.

- Good hardenability: Ensures uniform performance across the entire valve body with no soft spots.

Manufacturing and Processing:

- Forging is typically used to achieve a denser metallographic structure.

- Quenching and tempering heat treatment is key to achieving the aforementioned mechanical properties.

- Nondestructive testing (100% ultrasonic UT and magnetic particle MT testing) is mandatory to ensure the absence of internal and surface defects.

2. Flanges, Clamps & Connectors

Applicable Components: Tubing head flanges, casing head flanges, clamp-type connectors, nuts and bolts.

Operating Characteristics: Withstands extremely high tensile, bending, and sealing loads, ensuring the integrity of the connection and seal throughout the Christmas tree.

Core Performance Requirements:

- High Strength and Hardness: Ensures sufficient rigidity, minimizes deformation under bolt preload and internal pressure, and maintains a tight seal.

-Required Indicators: Strength requirements are similar to those for the valve body, with a hardness range typically controlled between HRC 22-34.

- Suitable Toughness: Prevents cracking during tightening or operation.

- Isotropic Properties: Forgings should exhibit uniform properties in all directions to avoid performance shortcomings.

Manufacturing and Processing:

- Must be forged.

- Also requires quenching and tempering and comprehensive non-destructive testing.

- Sealing surfaces typically require a surface hardening treatment (such as carbide overlay) for wear resistance.

3. Valve Stem, Gate, & Throttle Valve Plug

Applicable Components: Gate valve stems and gates; throttle valve cages and valve plug housings.

Operating Characteristics: Subject to wear, erosion (especially in the throttle components), shear forces, and friction.

Core Performance Requirements:

- High surface hardness and wear resistance: Resists friction and erosion from high-velocity fluids.

-Required Specifications: Surface hardness of HRC 40-55 (achieved through surface heat treatment or nitriding).

- Strong Core: Ensures components do not fracture under load.

-Required Specifications: Core toughness must still meet impact energy requirements.

- Fatigue Resistance: Components such as valve stems withstand the alternating stresses of reciprocating motion.

Manufacturing and Treatment:

Using a “case hardening” process, such as nitriding, to form an extremely hard and wear-resistant nitride layer on the surface while maintaining the core’s toughness.

A common and critical special requirement: Corrosion Resistance

Regardless of the component, corrosion must be considered if the component is used in an oil and gas environment.

1. Surface Corrosion Protection (All Operating Conditions):

- Requirement: 4140 steel is inherently corrosion-resistant and requires a protective coating.

- Solution: Nickel-phosphorus (ENP) plating is the most commonly used and effective process. The coating must be dense, non-porous, and uniformly thick (typically ≥ 75 μm), and its corrosion resistance must be verified through autoclave testing.

2. Sulfide Stress Cracking (SSC) Resistance (Sour Operating Conditions):

- Requirement: In “sour environments” containing hydrogen sulfide (H₂S), the material is extremely sensitive to SSC.

- Key Parameter: According to NACE MR0175/ISO 15156 standards, the material hardness must be strictly limited to ≤ 22 HRC (HBW 237).

- Achievement: Quenching and tempering treatment at a higher tempering temperature, sacrificing some strength in exchange for extremely high toughness and SSC resistance. This places extreme demands on the heat treatment process.

Summary table: Overview of the performance requirements of 4140 steel in Christmas tree applications

| Application Components | Core Working Conditions | Key Performance Requirements |

| High-pressure valve body | High pressure, pressure fluctuation, shock resistance | Ultra-high strength (YS ≥ 758MPa), ultra-high toughness (CVN ≥ 54J @ -18°C), fatigue resistance |

| Flanges, clamps, connectors | High tensile, bending, sealing loads | High strength, high stiffness, isotropic performance |

| Valve Stem, Gate, & Throttle Valve Plug | Wear, erosion, friction | High surface hardness, wear resistance, strong core |

| All components (common) | Corrosive media | Corrosion resistant |

| All components (sour environment) | H₂S | Sulfide stress cracking (SSC) resistant |

In short, the application of 4140 steel in Christmas trees is a process of tailoring the components to their specific operating conditions. Manufacturers utilize precise heat treatment processes and rigorous quality inspection standards to maximize the potential of 4140 steel, making it the “steel backbone” that ensures the safe operation of oil and gas wells.