AISI 5140 | 41Cr4 | DIN 1.7035 Alloy Steel

AISI 5140 Alloy steel manufacturers and suppliers, supplied in round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

AISI 5140 alloy steel is a structural alloyed carbon steel accding to AISI/ASTM standard which is widely used in Low and moderately stressed parts for vehicles, engines and machines where hard, wear resisting surface is needed. The hardness as surface hardened is about 54 HRC.

1.Chemical Composition

Grade C Mn Si P S Cr

5140 0.38-0.43 0.7-0.9 0.15-0.35 ≤ 0.035 ≤ 0.04 0.7-0.9

2245 0.38-0.45 0.6-0.9 0.15-0.4 ≤ 0.035 0.02-0.04 0.9-1.2

41Cr4/1.7035 0.38-0.45 0.6-0.9 ≤ 0.4 ≤ 0.025 ≤ 0.035 0.9-1.2

2.Related Specifications

EN/DIN:41Cr4/1.7035

GB: 40Cr

JIS:SCr440

BS:530M40

3.Heat Treatment & Mechanical Property

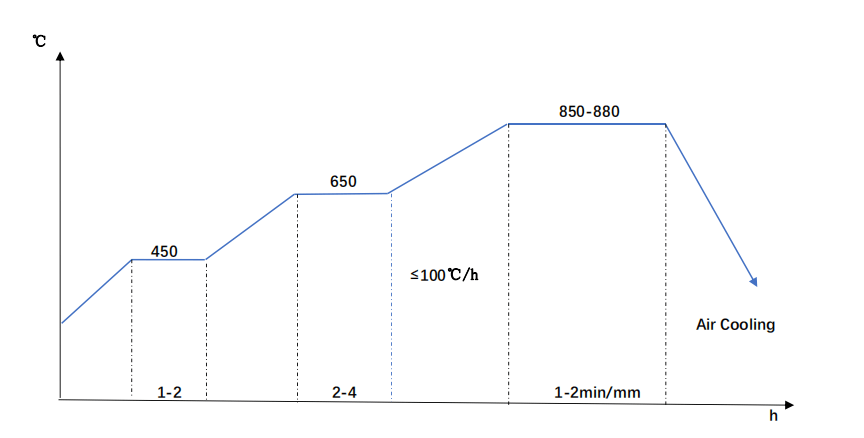

AISI 5140 Steel Normalizing Diagram

AISI 5140 Steel Normalizinging Details

1.Normalize temperature:850-880℃

2.Three steps for temperature raising.

3.Proper holding time depends on the dimension.

4.Air cooling.

5.Max hardness:229HB

AISI 5140-Mechanical Property With Normalizing

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Temperature |

| ≥740Mpa | ≥460Mpa | ≥17% | ≥62% | ≥108J | 860℃ |

AISI 5140 Steel Annealing Diagram

AISI 5140 Steel Annealing Details

1.Annealing temperature:830-850℃

2.Enough soaking time for the steel heating

3.Cooling in the furnace.

4.Max hardness:200HB

AISI 5140-Mechanical Property With Annealing

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Temperature |

| ≥692Mpa | ≥396Mpa | ≥19% | ≥51% | ≥82J | 850-860℃ |

| ≥660Mpa | ≥410Mpa | ≥16% | ≥66% | ≥126J | 910℃ |

4.Supply Size & Condition

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1,000 | 3,000-10,000 |

| Square bar | 100x100-600x600 | 3,000-6,000 |

| Plate/Sheet | Thickness :20-400 Width:80-1,000 | 2,000-6,000 |

| Flat bar/Blcoks | Thickness :120-800 Width:120-1,500 | 2,000-6,000 |

Heat treatment:Normalized / Annealed / QT

Surface finish:Black / Rough turned / Peeled