DIN 1.7035|41Cr4 |AISI 5140 | 530M40 Alloy Steel

DIN 1.7035 / 41Cr4 Alloy Steel manufacturers and suppliers,supplied with round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

DIN 1.7035 / 41Cr4 Alloy Steel is one of the most widely used alloy steel which has good comprehensive mechanical properties,low temperature impact toughness and hardenability after QT heat treatment. DIN 1.7035 / 41Cr4 Alloy Steel can be used in the manufacture of medium speed,the load of parts,such as machine tools gear,shaft,worm,etc.

1.Chemical Composition

| Grade | C | Si | Mn | Cr | P | S |

| 41Cr4/1.7035 | 0.38-0.45 | ≤ 0.4 | 0.6-0.9 | 0.9-1.2 | ≤ 0.025 | ≤ 0.035 |

| 5140 | 0.38-0.43 | 0.15-0.35 | 0.7-0.9 | 0.7-0.9 | ≤ 0.035 | ≤ 0.04 |

| 530M40 | 0.36-0.44 | 0.1-0.4 | 0.6-0.9 | 0.9-1.2 | ≤ 0.035 | ≤ 0.04 |

2.Related Specifications

AISI/ASTM:5140,2245

GB: 40Cr

JIS:SCr440

BS:530M40

3.Heat Treatment & Mechanical Property

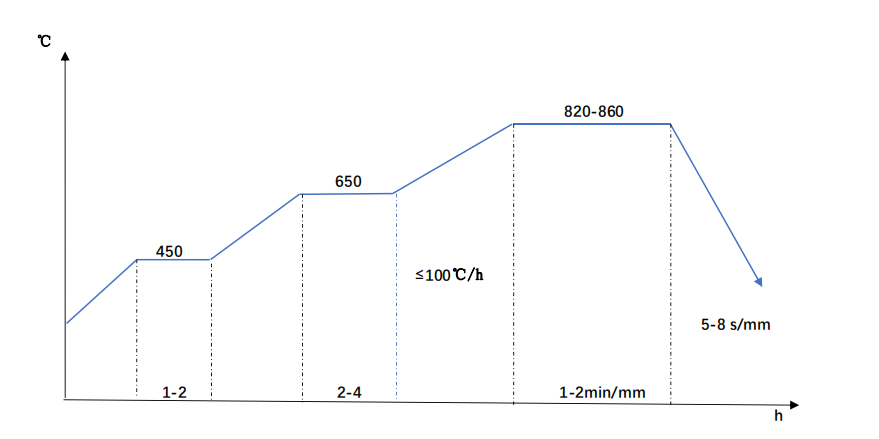

41Cr4 Quenching Diagram

41Cr4 Steel Quenching Details

1.Quench temperature:820-860℃

2.Keep suitable time for the steel to be thoroughly heated.

3.Oil or water quench.

4.Tempering immediately after quenched.

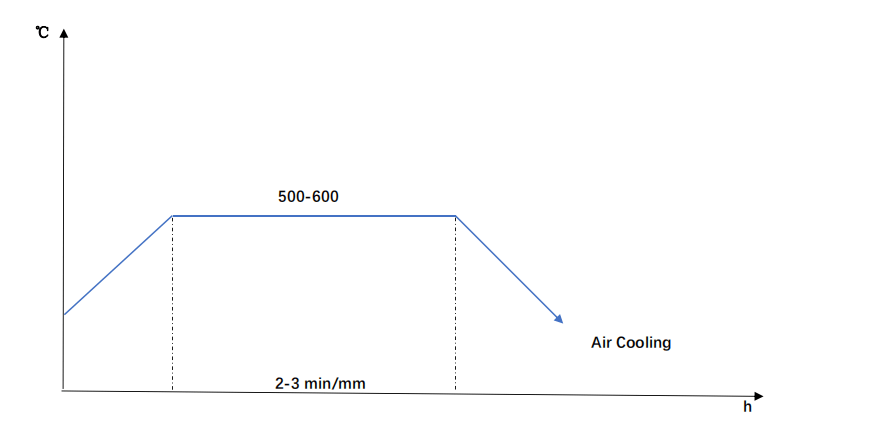

41Cr4 Tempering Diagram

41Cr4 Steel Tempering Details

1.Temper temperature:500-600℃

2.Air cooling.

41Cr4-Mechanical Property With Quenching and Tempering

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

| ≥1000Mpa | ≥800Mpa | ≥9% | ≥45% | ≥60J | 28-34HRC |

41Cr4 Hardness Vs Tempering temperature

| Temperature,℃ | 150 | 200 | 300 | 400 | 500 | 550 | 600 | 650 |

| Hardness,HRC | 55 | 53 | 51 | 43 | 34 | 32 | 28 | 24 |

4.Supply Size & Condition

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1,000 | 3,000-10,000 |

| Square bar | 100x100-600x600 | 3,000-6,000 |

| Plate/Sheet | Thickness :20-400 Width:80-1,000 | 2,000-6,000 |

| Flat bar/Blcoks | Thickness :120-800 Width:120-1,500 | 2,000-6,000 |

Heat treatment:Normalized / Annealed / QT

Surface finish:Black / Rough turned / Peeled