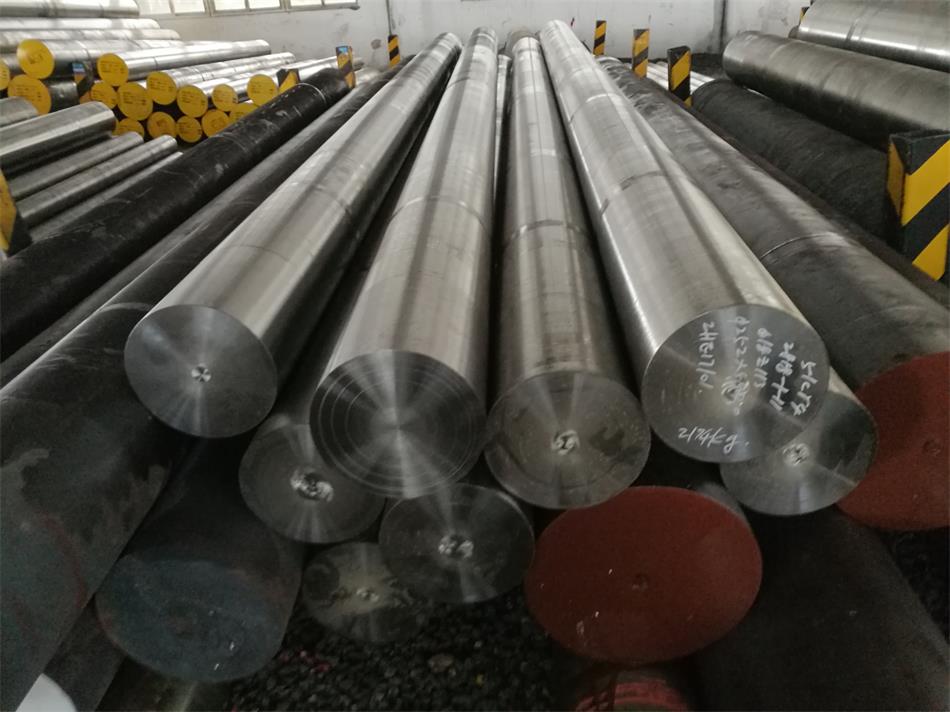

C40 Carbon Steel |DIN 1.0511|AISI 1040|S40C

C40 carbon steel has high carbon content and can be hardened by heat treatment followed by quenching and tempering to achieve 150 to 250 ksi tensile strength.it is usually supplied as forged or normalized condition.

C40 carbon steel can be welded using all welding techniques with the correct procedure,and it has good machinability(rate at 60) after full annealing.it also can be hardened by flame or induction hardening with a typical hardness of Rc 50-55.

1.C40 steel Supply Form & Size

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1000 | 3000-10000 |

| Square bar | 100 x 100-600x600 | 3000-6000 |

Flat bar/Blcoks | Thickness :120-800 | 2000-6000 |

| Width:120-1500 |

2.Surface Finish&Tolerance

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

3.C40 Steel Chemical Composition&Related Specifications

| Grade | C | Si | Mn | P | S |

| C40/1.0511 | 0.37-0.44 | ≤ 0.4 | 0.50-0.80 | ≤ 0.045 | ≤ 0.045 |

| USA | UK | China | Japan |

| 1040 | 080M40/080A40 | 40# | S40C |

4.C40 Steel Mechanical Property

| Diameter d mm | ≤ 16 | 16-40 | 40-100 |

| Thickness t mm | < 8 | 8-20 | 20-60 |

| Yield Strength Mpa | ≥460 | ≥400 | ≥350 |

| Tensile Strength Mpa | 650-800 | 630-780 | 600-750 |

| Elongation, % | ≥16 | ≥18 | ≥19 |

| Reduction of area ,% | ≥35 | ≥40 | ≥45 |

5.C40 steel Forging

Forging temperature:950-1250℃,air cooling after forging.

6.Heat Treatment For C40 Steel

- Normalizing

The normalizing temperature range for this grade is typically 870-900ºC,followed by cooling in still air.

- Annealing

Full annealing of small C40 forgings is carried out from 840-890ºC,followed by furnace cooling at 28ºC per hour, to 650ºC soaking and air cooling.

- Hardening

Hardening of this grade is carried out from an austenitizing temperature of 830-860ºC followed by oil or water quenching.

- Tempering

Tempering after normal hardening and oil or water quenching is carried out at 400-680ºC to give the required mechanical properties as determined by practical experience.

7.C40 Steel Application

This grade of steel is used for forged parts where the strength and toughness of the material are appropriate. C40 may be used for the manufacture of forged crankshafts ,couplings, and cold headed parts,along with a range of parts where the properties of heat-treated C40 are suited to the application.