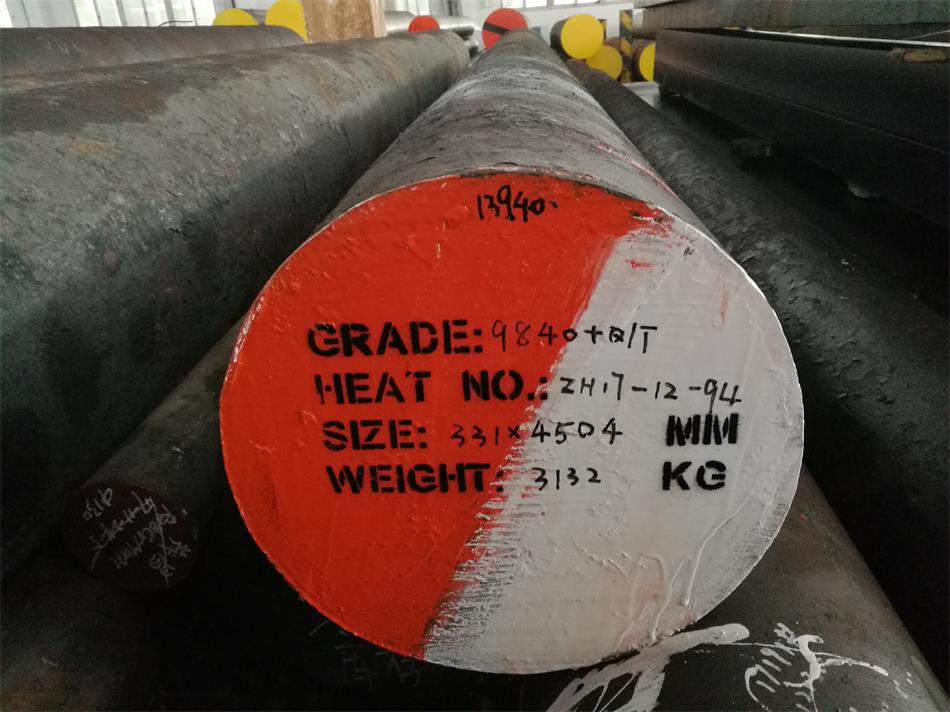

AISI 9840 Alloy Steel | 36CrNiMo4 | DIN 1.6511 | 39NiCrMo3

AISI 9840 is a nickel-chrome-molybdenum steel which contains at least 0.85%Ni,0.7%Cr,0.2%Mo as strengthening alloy elements.It is suitable for different heat treatment and shows excellent hardenability, strength,toughness and good cold workability.After annealing,this material becomes machinable and adjusted for the mechanical cutting.pre-heat and post-weld stress relief are necessary for welding of this alloy,but welding in the hardened and tempered condition is not recommended.

1.AISI 9840 steel Supply Form & Size

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1,000 | 3,000-10,000 |

| Square bar | 100x100-600x600 | 3,000-6,000 |

| Plate/Sheet | Thickness :20-400 Width:80-1,000 | 2,000-6,000 |

| Flat bar/Blcoks | Thickness :120-800 Width:120-1,500 | 2,000-6,000 |

2.Surface Finish&Tolerance

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

3.Chemical Composition&Related Specifications

| C | Mn | P | S | Si | Ni | Cr | Mo |

| 0.38-0.43 | 0.7-0.9 | 0.04 | 0.04 | 0.2-0.35 | 0.85-1.15 | 0.70-0.90 | 0.20-0.30 |

| Germany | Russia | Italy | France |

| 36CrNiMo4/1.6511 | 36HNM | 39NiCrMo3 | 40NCD3 |

4.Mechanical Property

| Diameter d mm | ≤ 16 | 16-40 | 40-100 | 100-160 | 160-250 |

| Yield Strength Mpa | ≥900 | ≥800 | ≥700 | ≥600 | ≥550 |

| Tensile Strength Mpa | 1100-1300 | 1000-1200 | 900-1100 | 800-950 | 750-900 |

| Elongation, % | ≥10 | ≥11 | ≥12 | ≥13 | ≥14 |

| Reduction of area ,% | ≥45 | ≥50 | ≥55 | ≥60 | ≥60 |

| impact,J | ≥35 | ≥40 | ≥45 | ≥45 | ≥45 |

| Hardness,HB | 331-380 | 298-359 | 271-331 | 240-286 | 225-271 |

5.Forging for AISI 9840

Forging AISI 9840 steel between 1100℃-11500℃,and reheat the steel once temperature below 950℃.AISI 9840 has good forging characteristics,but this material is easy to crack when cooling improperly,Cooling in sand or in the furnace after forging is recommended.

6.Heat Treatment

- Normalizing:850℃-880℃,Cool in air

- Soft Annealing:650℃-700℃,Cool in furnace

- Full Annealing:830℃-850℃,Cool in furnace,235HB max

- Hardening:830℃-865℃,water or oil quench

- Tempering:540°C – 680°C, cool in still air

7.Machinability

This material may be readily machined, preferably from a coarse pearlitic structure.

8.Application

This alloy is suitable for production of highly stressed components of large cross section for aircraft, automotive and general engineering applications, such as forged propeller shafts, connecting rods, gear shafts, crankshafts and landing gear components.