36CrNiMo4 Round bar-EN10250 | DIN 1.6511| SNCM439

36CrNiMo4/DIN 1.6511 Alloy steel manufacturers and suppliers, supplied in round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

36CrNiMo4 Steel is defined as Ni-Mo steel as per EN10250 Standard.It has good comprehensive mechanical properties which is known for its toughness and capability of developing high strength in the heat treated condition while retaining good fatigue strength.36CrNiMo4 alloy steel is widely used in permanently stressed components with large cross sections for automotive and mechanical engineering.Typical use are crankshafts, connecting-rods, pump and press, control parts, steam turbine shafts and rings.

1.Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 36CrNiMo4/1.6511 | 0.32-0.4 | ≤ 0.4 | 0.5-0.8 | ≤ 0.035 | ≤ 0.035 | 0.9-1.2 | 0.9-1.2 | 0.15-0.3 |

2.Related Specifications

ASTM:9840

BS:EN24/817M40

JIS:SNCM439

GB:40CrNiMo

3.Heat Treatment & Mechanical Property

- Normalizing: 850 – 880°C,Cooling in air

- Annealing:650 – 700°C,Cooling in furnace

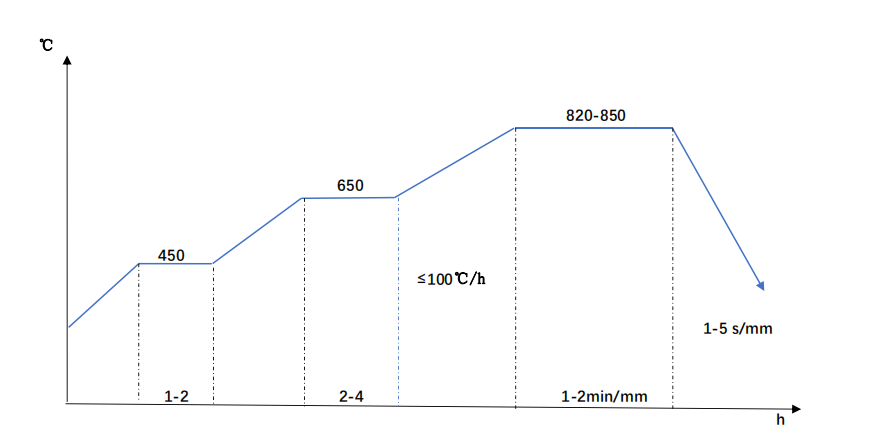

- Hardening:820 – 850°C,oil or water quench

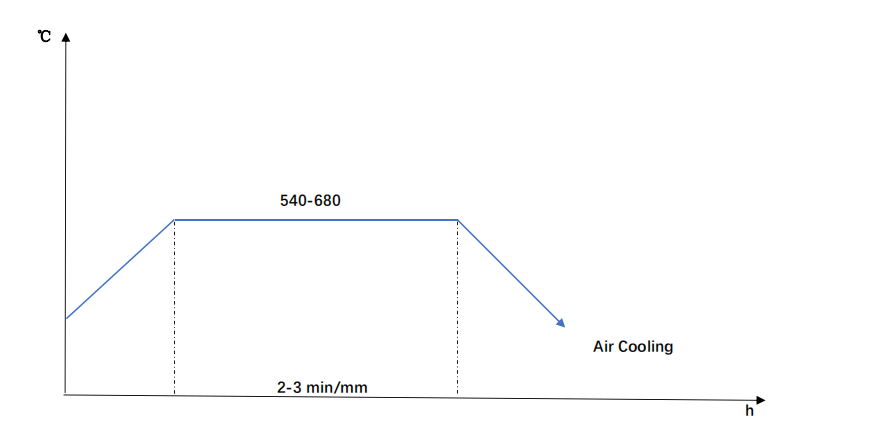

- Tempering:540 – 680°C,Cooling in air

36CrNiMo4 Tempering Diagram

36CrNiMo4 Mechanical Property With Quenching and Tempering condition

| Size mm | Tensile Strength,Min Mpa | Yield Strength,Min Mpa | Elongation,Min % | Impact Charpy-V,Min J |

| ≤160 | 750 | 550 | L:14 T:10 | L:45 T:22 |

| 160-330 | 700 | 500 | L:15 T:11 | L:45 T:22 |

| 330-500 | 650 | 450 | L:16 T:12 | L:40 T:20 |

4.Supply Form & Size

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.16 – 130mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled